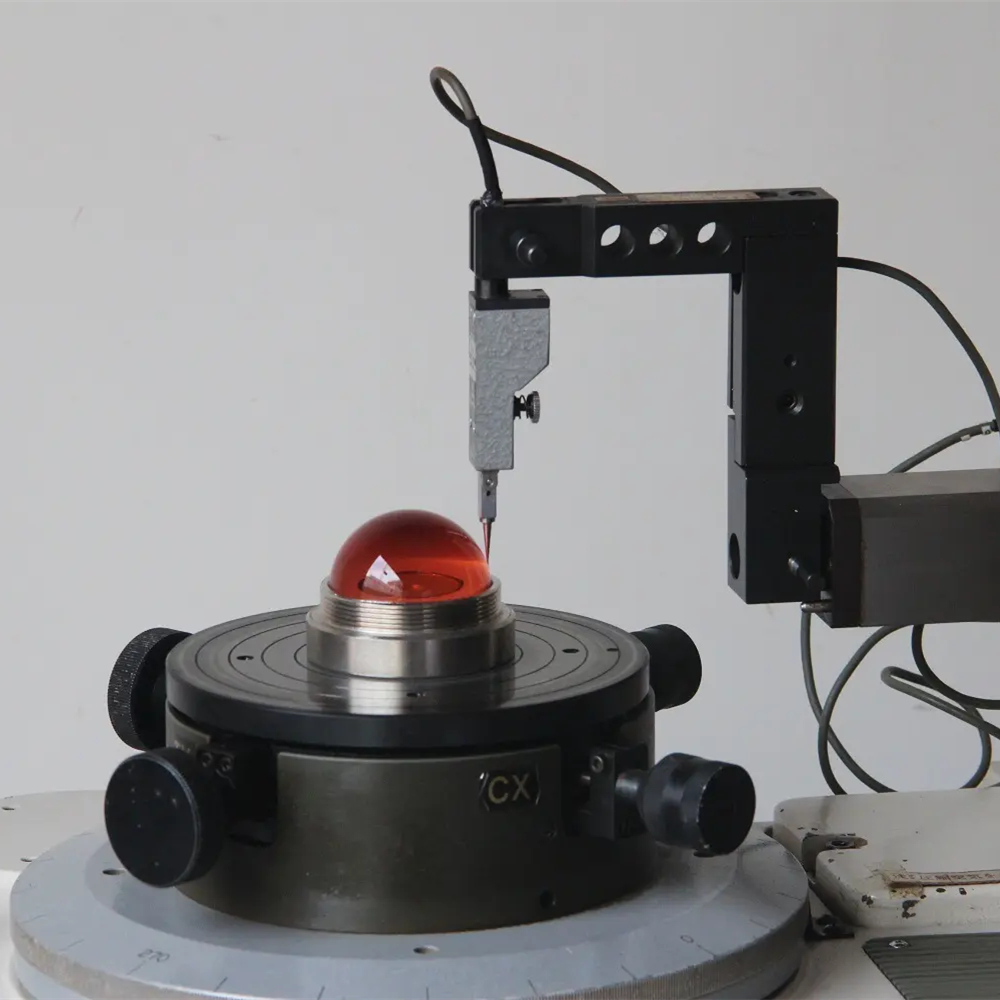

Roundness measurement profile measurement instrument

$16000≥1Set/Sets

| Payment Type: | T/T,D/P,D/A |

| Incoterm: | EXW,CIF,CFR,Express Delivery,FCA |

| Min. Order: | 1 Set/Sets |

| Transportation: | Ocean,Express |

| Port: | Ningbo Port |

$16000≥1Set/Sets

| Payment Type: | T/T,D/P,D/A |

| Incoterm: | EXW,CIF,CFR,Express Delivery,FCA |

| Min. Order: | 1 Set/Sets |

| Transportation: | Ocean,Express |

| Port: | Ningbo Port |

Model No.: DC30

Brand: DEXUN

Certification: Reach, Scoc

Support Customization: Obm, Odm

Place Of Origin: China

Maximum Diameter Measurement Range: 300

Minimum Inner Diameter Measuring Range: 5

Maximum Height Measurement Range: 400

| Selling Units | : | Set/Sets |

| Package Type | : | Wooden case binding |

| Picture Example | : |

|

The file is encrypted. Please fill in the following information to continue accessing it

The cylindricity meter is a rotary table cylindricity meter with a computer measurement system based on the precision air floating spindle and high-precision column guide rail. It is mainly used to measure the roundness, cylindricity, waviness, coaxiality, concentricity, perpendicularity, parallelism, straightness and other parameters of rotary workpieces such as rings and cylinders.

The roundness and Cylindricity Measuring Instrument can be widely used in automobile parts, bearings, machine tools, oil pump nozzles, aerospace and other precision machinery manufacturing enterprises, colleges and universities, scientific research institutions, measurement institutions, etc.

Instrument characteristics:

1.The main shaft adopts ultra high precision air floating shaft, so that the instrument has the advantages of high rotation accuracy, good stability, strong bearing capacity, non-contact, non wear, and long life, reaching the national first-class accuracy standard.

2.Measuring cylindricity of workpiece with multi section method

3.High precision column guide rail ensures high accuracy and repeatability of workpiece cylindricity measurement.

4.The worktable and column are made of natural granite to make the mechanical performance of the instrument more stable and reliable, without deformation, drift and beautiful.

5.The two-stage built-in air filter, a protective pressure relay and an oil-water separator device make the working air pressure of compressed air stable, clean and dry, and ensure good rotation stability and high accuracy of the air floating spindle.

6.The vertical and horizontal movement of the sensor is driven by a linear motor, which makes the instrument easy to operate and accurate to adjust.

7.2048 line/cycle high-precision rotary encoder is adopted to ensure the data sampling resolution.

8.The inductance signal measuring circuit of the instrument is a high-precision LVDT special circuit independently developed by our company, and the measuring accuracy and stability are at the leading level in China.

9.The special measurement analysis management software based on Windows XP operating system has the functions of automatic collection, automatic correction of eccentricity, instrument calibration, digital filtering, measurement parameter evaluation in accordance with the latest ISO standard, measurement result database archiving, printing and output, etc

The roundness meter is a length measuring tool that uses the rotary axis method to measure the roundness. The roundness tester is a measuring tool for measuring the roundness error of workpieces by using the rotary axis method. The roundness tester is divided into two types: sensor rotary type and workbench rotary type. During measurement, the measured part and the precision shaft system are installed concentrically, and the precision shaft system is equipped with an inductive length sensor or a workbench for precise circular motion. It is composed of sensor, amplifier, filter and output device of the instrument. If the instrument is equipped with a computer, the computer is also included in this system.

Principle of roundness tester

The principle of the roundness meter is the same as that of the three coordinate measuring machine. In fact, its working principle is very simple. The three coordinate measuring machine is a point acquisition tool. Its principle is to first acquire points, then form a line from points, and then form a three-dimensional model from lines. CMM is a kind of measuring equipment with guiding mechanism, length measuring element and digital display device in three mutually perpendicular directions, a workbench (not necessarily large or giant) that can place workpieces, the measuring head can be moved to the measured point quickly and manually or mechanically, and the coordinate value of the measured point is displayed by the data reading equipment and digital display device. Obviously, this is the simplest and most primitive measuring machine. With this measuring machine, the coordinate value of any point in the measuring volume can be displayed through a reading device and a digital display device.

The cylindricity meter is a rotary table cylindricity meter with a computer measurement system based on the precision air floating spindle and high-precision column guide rail. It is mainly used to measure the roundness, cylindricity, waviness, coaxiality, concentricity, perpendicularity, parallelism, straightness and other parameters of rotary workpieces such as rings and cylinders.

The instrument is mainly composed of high-precision air floating spindle, precision leveling and centering worktable, high-precision granite column, granite table top, high-precision inductive probe, precision rotary encoder, drive control electric box, high-precision measurement electric box, air filtering and drying system and special measurement and analysis software based on Windows XP.

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Fill in more information so that we can get in touch with you faster

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.