Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

The tangent method is simple to operate, but has low reading density, making it suitable for rapid batch testing. If the angle density reading requirement of the tested object is high, another method, namely the sampling point calculation method, is more suitable. All geometric elements have certain combinations, including the Urelement of lines, curves and arcs. A two-dimensional plane angle is composed of two basic geometric elements: straight lines, which are composed of countless points. Therefore, regardless of whether the angle measurement is accurate or not, the mining point is the most crucial.

Due to limited screen display and high magnification (usually 0.7x-4.5x/34x-220x), the workpiece size displayed on the screen is only a few millimeters. Many surveyors only use it to collect the points and lines displayed on the screen during testing. If there is a deviation in the collection point, the shorter the linear segment, the greater the deviation in the measurement angle value. The longer the linear segment, the smaller the deviation in the measurement angle value. So when we measure the angle, we try to collect the lines on both sides of the angle. If the screen display range is too small, we can move the workbench and select a point at the starting point of the straight line where the angle is located, and then select a point at the end point, which can greatly reduce the error of angle measurement.

Automatic imager angle measurement technology: small deviation of regression line.

Many inspectors replied that the repeatability accuracy when measuring angles is very poor. In the same method used by the same person, the repetition error of two measurements can reach up to 0.5 degrees. Many image measurement software, including coordinate measurement software, default the collection of straight lines to two points. For some conventional parts with good linearity, it will not cause too much error, but for parts with poor linearity and more burrs, using the two-point straight line acquisition method will bring significant error and poor repeatability accuracy. Repeated measurement of such a straight line angle is definitely not good.

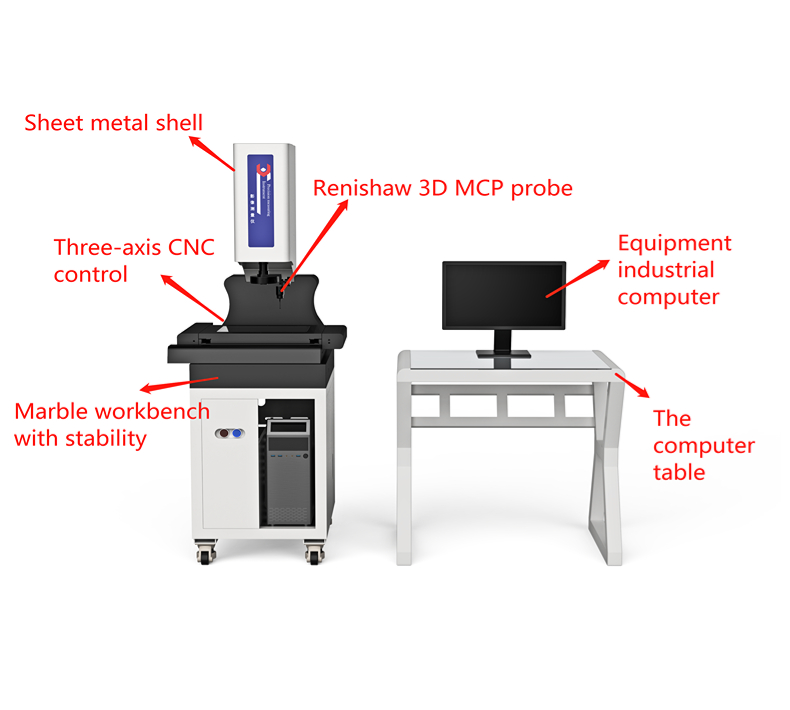

From the moment when the second-dimensional image measuring instrument appeared, the precision measuring instrument really entered the development era of high-precision measuring instrument. It was...

Can a fully automatic 3D image measuring instrument measure height? How much can a typical accuracy cost? Two dimensional measuring instrument, also known as image measuring instrument, is a...

Email to this supplier

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Fill in more information so that we can get in touch with you faster

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.