Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

As a core competitive product, video measuring instruments have chips that are only two to three centimeters small, but are densely arranged with tens of millions of lines, each direction in an orderly manner. Traditional measurement techniques are difficult to achieve high-precision and efficient chip size detection. Based on image processing technology, video measuring instruments can quickly obtain geometric parameters of objects through image processing, and then complete the measurement through software analysis.

With the rapid development of integrated circuits, the circuit width of chips is becoming smaller and smaller. The Haykes rehabilitation composite video image Measuring Instrument amplifies a certain number of times through a low light system, and then transmits the low light image to a computer through an image sensor for image processing and measurement.

In addition to conventional dimensions, the core of chip detection is focused on the vertical distance between the pin vertices of the chip and the solder pads. If there is a deviation in the distance between the top of the pin and the welding pad, it will not only cause a mismatch between the repair welding and the bottom of the pin, but also lead to welding leakage, which cannot guarantee the quality of the finished product. Therefore, manufacturers have very strict requirements for the size detection of video measuring instruments.

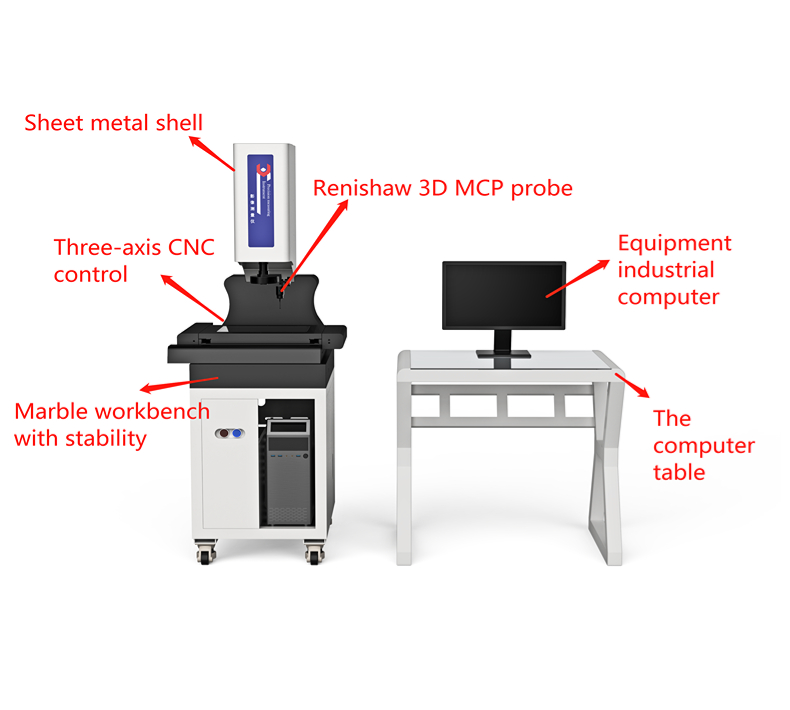

At present, in the market, the measurement of vertical spacing size from needle tip to welding plate mainly relies on high-precision image measuring instruments. By capturing the size characteristics of the chip through the CCD lens of the image measuring instrument, high-definition images can be quickly captured. Computers convert imaging information into dimensional data, perform error analysis, and measure accurate dimensional information. The working principle of the image measuring instrument is basically the same, but the configuration of the machine and software is different. Generally speaking, image measurement instrument manufacturers have low prices and can meet the requirements of high-precision detection.

From the moment when the second-dimensional image measuring instrument appeared, the precision measuring instrument really entered the development era of high-precision measuring instrument. It was...

Can a fully automatic 3D image measuring instrument measure height? How much can a typical accuracy cost? Two dimensional measuring instrument, also known as image measuring instrument, is a...

Email to this supplier

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Fill in more information so that we can get in touch with you faster

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.