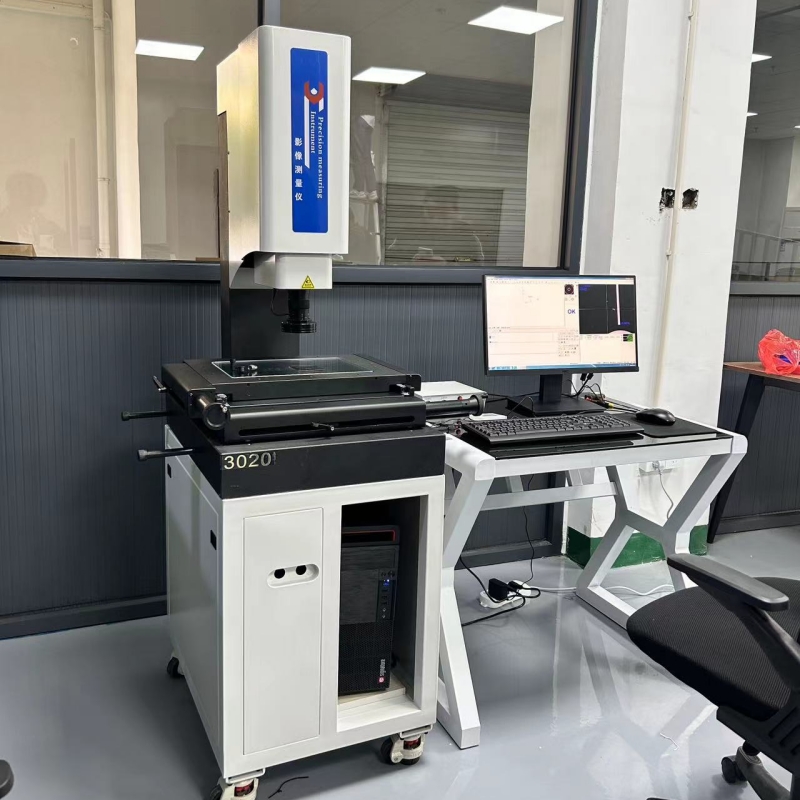

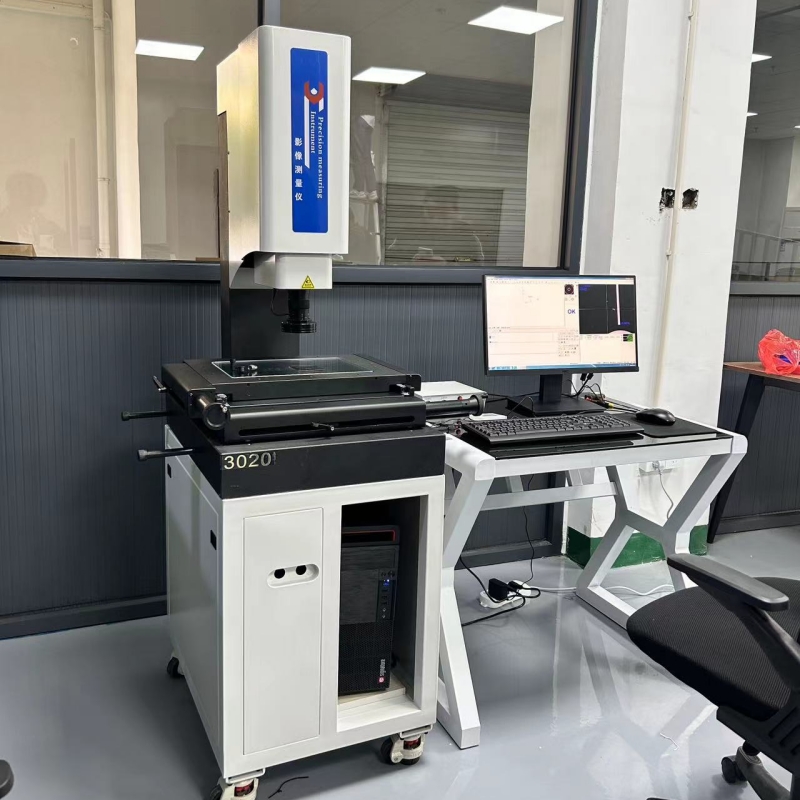

Video image

Measuring Instrument is a high-precision and precise measuring instrument that integrates light, electricity, and machinery. It must have excellent maintenance and upkeep to maintain the excellent application of the instrument. That way, we can maintain the original precision of the instrument and increase its lifespan.

Maintenance:

1. The anime imager should be placed in a clean and dry room (the indoor temperature is 20 ℃± 5 ℃, and the ambient humidity is less than 60%) to prevent the surface of electronic optical parts from being damaged, metal material parts from being rusted, and floating dust and dirt from falling into the fitness track, endangering the characteristics of the instrument.

2. After the application of the image measuring instrument is completed, the excavation working face should be cleaned and tidy anytime and anywhere, preferably covered with a dust cover.

3. The transmission mechanism of the imaging device and the fitness exercise slide should be lubricated on time to ensure smooth and stable application of the organization's fitness exercise.

4. The surface of laminated glass and paint on the anime console is dirty, which can be cleaned with neutral detergent and cold water. Never use solvents to scrub the surface of paint, otherwise it will make the paint surface dull.

5. The LED light source of the anime image measuring instrument has a long service life, but when a light bulb is burned out, please notify the manufacturer, and the technical professional staff will replace it for you.

6. The high-precision components of the image measuring instrument, such as the image system software, operating platform, electronic optical ruler, and its Z-axis transmission mechanism, all require high-precision calibration. All adjustment screws and tightening screws are fixed and cannot be moved. Customers should not disassemble them independently. If there are any problems, please inform the manufacturer for processing.

7. The anime software has made accurate compensation for the deviation between the operating platform and the electronic optical ruler, and should not be changed independently. Otherwise, it will result in inaccurate and precise measurement results.

8. All electrical equipment connectors of the X-ray real-time imaging flaw detector generally do not need to be unplugged. If they have been unplugged, they must be properly plugged back in according to the identification and the screws must be tightened. Incorrect wiring can harm the function of the instrument, and in severe cases, it is highly likely to damage the system software.