Large Size Automatic Vision Measuring Instrument

$8800-16300 /Set/Sets

| Payment Type: | D/A,D/P,T/T,L/C |

| Incoterm: | CFR,CIF,EXW,FCA,Express Delivery,FOB |

| Min. Order: | 1 Set/Sets |

| Transportation: | Ocean,Express |

| Port: | Ningbo Port,Zhoushan Port |

$8800-16300 /Set/Sets

| Payment Type: | D/A,D/P,T/T,L/C |

| Incoterm: | CFR,CIF,EXW,FCA,Express Delivery,FOB |

| Min. Order: | 1 Set/Sets |

| Transportation: | Ocean,Express |

| Port: | Ningbo Port,Zhoushan Port |

Model No.: CNC3020

Brand: DEXUN

Certification: Reach, Scoc

Support Customization: Odm, Obm

Place Of Origin: China

Size: 300*200*180

Overall Dimensions: 580*680*980

| Selling Units | : | Set/Sets |

| Package Type | : | Wooden case binding |

| Picture Example | : |

|

The file is encrypted. Please fill in the following information to continue accessing it

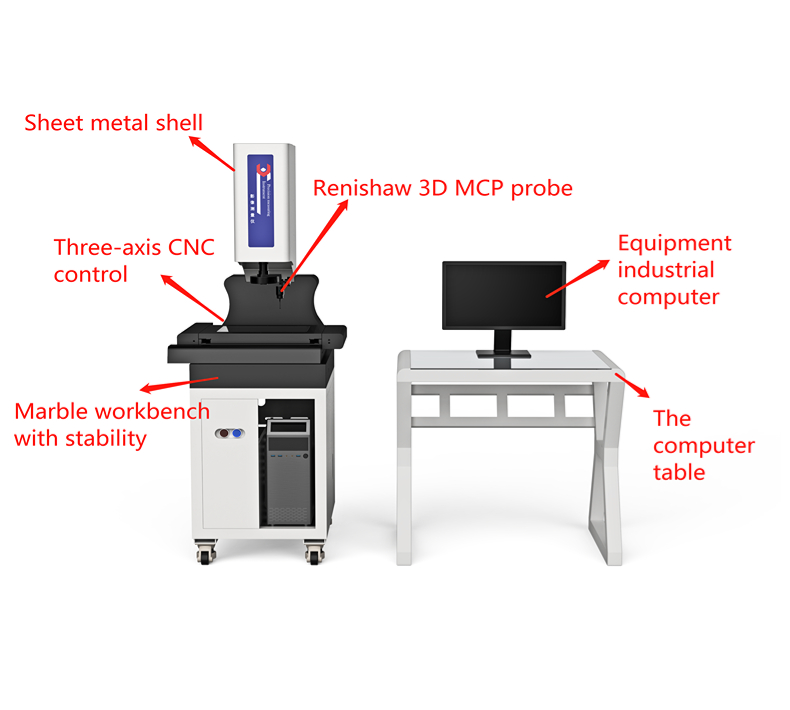

Full-automatic image Measuring Instrument, which is based on artificial intelligence technologies such as automatic edge extraction, automatic matching, automatic focusing, measurement synthesis, image synthesis, etc. of machine vision, has the functions of automatic measurement of where to go, automatic measurement of CNC walking, automatic learning batch measurement, image map target guidance, full-field eagle eye magnification, etc. At the same time, it is based on the automatic focusing process under the precise control of machine vision and micrometer, which can meet the need for auxiliary height measurement under clear contrast (a contact probe can also be added to complete coordinate height measurement). It supports the software performance of spatial coordinate rotation. It can conduct batch measurement when the workpiece is placed at will and can also use the fixture to conduct mass scanning measurement and SPC result classification.

The image-measuring instrument is based on automatic edge extraction, automatic matching, automatic focusing, measurement synthesis, image synthesis, and other artificial intelligence technologies of machine vision. It has the functions of automatic measurement of where to go, automatic measurement of CNC walking, automatic learning and batch measurement, image map target indication, entire field eagle eye magnification, and other excellent functions. At the same time, the auto-focusing process based on machine vision and micrometer precision control can meet the needs of auxiliary measurement under clear images and add a contact probe to complete coordinate measurement. The excellent software performance supporting spatial coordinate rotation can be used for batch measurement and SPC result classification when the workpiece is randomly placed, or the fixture is used.

CNC is a series of Gantry CNC video measuring machines, which are specially designed for large size measurement. The largest measurement range can reach 400× 500mm, and can be applied in the industries of PCB, LCD, sheet metal, civil aviation and space industries, etc. VMG integrates the industry’s most advanced design concepts. The accuracy and stability of the machine can be ensured well on account of the most perfect design and strict controls during production.

Instrument characteristics:

1.Moving bridge structure, Automatic large volume measurement, four-axis CNC control.

2.Precision granite machines, high accuracy and stability.

3.Easily operated with mouse and joystick.

4.SIPOIN linear scales with high accuracy and stability.

5.World’s leading optical lens for programmable zoom measurement.

6.Programmable surface light (5 rings 8 octants, 48 sectors), LED profile light.

7.Automatic focus for height measurement. Touch probe can be added on demand.

8.Powerful ZONSON2D CNC metrology software.

9.Provide various standard configurations, customized versions are also available on demanded.

It can test the geometric element, including point, line, circle, arc, spline, ellipse, rectangle, slot, ring circle ,gap, distance, point list, etc.

It can construct centered, endpoint, insect, connect, parallel, perpendicular, tangent, bisect, combine, etc.

Video measuring tools include drawing point, closed point, focus point, pick point by circle, whole pick, multiple pick, edge trace, largest closed contour, nearest closed contour.

It can provide tolerance measurement: include straightness, roundness, position, parallelism, perpendicularity, angularity and concentricity, etc.

Coordinate system: Fixture positioning coordinate system, dotted line, Two points determine the X axis, Two points determine the Y axis, three points, two lines, Image registration system. Translation, rotation, manually adjust the coordinate system.

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Fill in more information so that we can get in touch with you faster

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.