The video

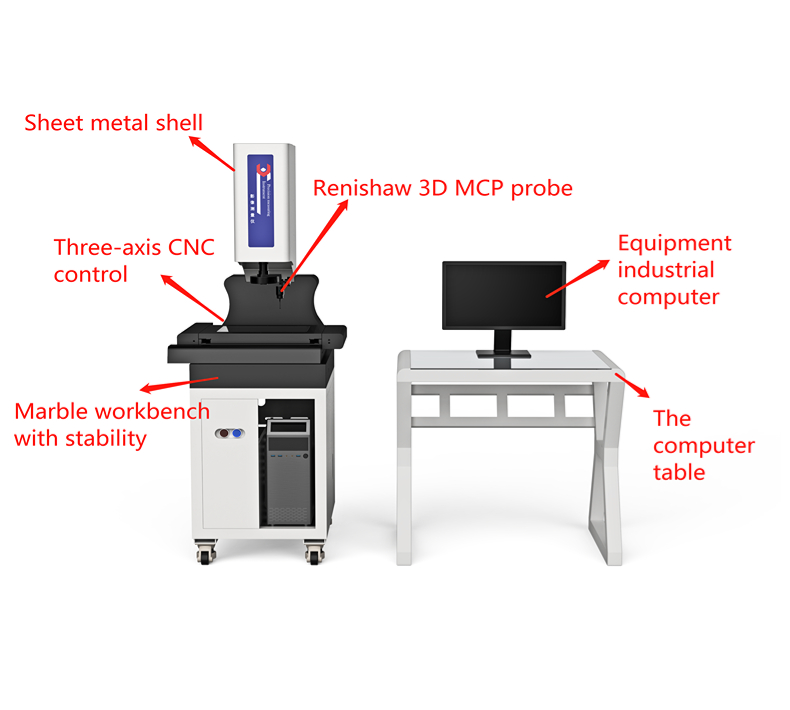

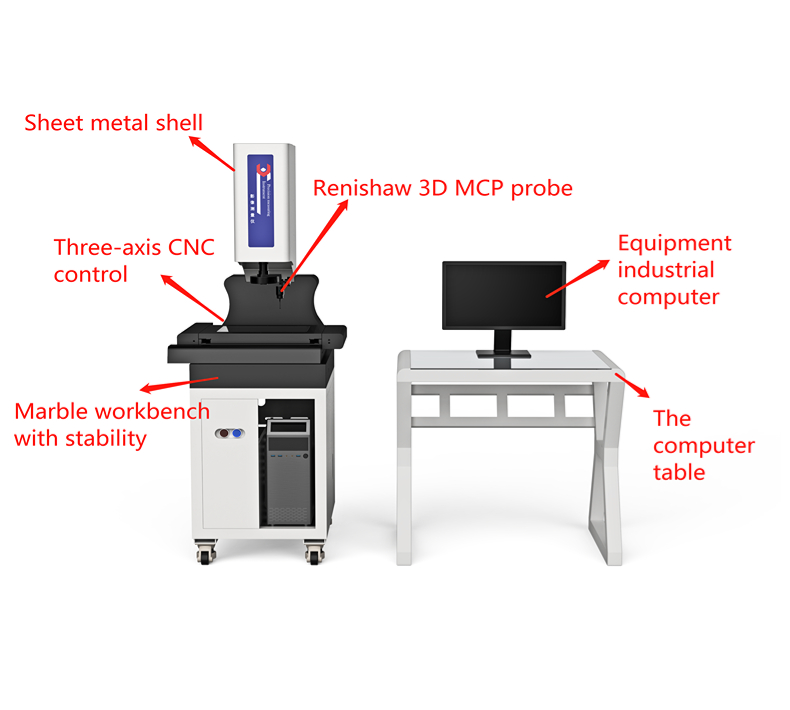

Measuring Instrument is based on CCD digital image and relies on the powerful software ability of computer screen measurement technology and spatial geometric operation. After the special control and graphic measurement software is installed on the computer, it becomes a measurement brain with the soul of the software. The manual image measuring instrument is the main body of the whole equipment.

It can quickly read the displacement value of the optical ruler. Through the operation of the software module based on spatial geometry, it can get the required results in real time, and generate graphics on the screen for the operator to compare the images, so as to directly identify the possible deviation of the measurement results. Video measuring instrument can be divided into manual video measuring instrument and automatic video measuring instrument. What is the difference between automatic video measuring instrument and manual video measuring instrument? Here is a brief introduction.

Differences between automatic video measuring instrument and manual video measuring instrument:

1. from the perspective of detection speed: the full-automatic is controlled by the program. Compared with manual video measuring instrument, the efficiency of batch detection of workpieces is greatly improved. It takes about five workpieces to manually detect one workpiece. For enterprises with heavy detection tasks, automatic detection of nearly five workpieces is more important. Automatic video measuring instrument is preferred.

2. from the perspective of detection accuracy: due to the use of program control, human interference factors are greatly reduced, and the workpiece detection accuracy is very important, which is extremely important for processing enterprises with more stringent requirements.

3. from the perspective of price factor, the price of video measuring instrument varies greatly due to the different software and hardware of full automata. Therefore, when selecting manual video measuring instrument and automatic video measuring instrument, users can select the appropriate model according to the needs of the enterprise and the needs of the next few years to avoid unnecessary losses.

4. from the characteristics of the machine tool, the automaton has a high-performance CNC full closed-loop servo control system. High speed and stable operation. The three shafts adopt German toothless screw drive technology. It will never wear out. It runs parallel, smooth and quiet. It has the functions of precise positioning, fast auto focusing, automatic edge finding, powerful programming and automatic measurement. Manual operation is manual operation, which can cut and move quickly. The z-axis is driven by toothless screws to achieve precise positioning. The report output function of semi-automatic image measuring instrument includes pictures and text, which can easily output the test results.

The above content is the introduction of automatic video measuring instrument and manual video measuring instrument. Economic development has led to steady growth in many industries. The development of handicraft industry will be replaced by automation industry. As an image measuring instrument in precision instruments, with the development of science and technology, video measuring instruments are also a qualitative leap on the basis of projectors. It improves the industrial measurement mode from the traditional optical projection to the computer screen measurement based on the digital image era.