The market competition for high-precision professional ultrasonic image measurement instruments is fierce. The customer will also compare several dealers when selecting them. Manufacturers present different product proposals for different user needs. How to compare the price of image measurement instruments to determine which well-known brand is the best choice?

1. The arrangement of the query measurement itinerary refers to the larger range that can be detected by each vertical coordinate. Different measurement schedule arrangements will immediately endanger the price of image measurement instruments. When selecting image measurement instruments, it is important to first grasp the product workpiece specifications that must be measured. The measurement schedule must be clearly defined based on the specifications of the products to be measured by the factory. If the measurement stroke arrangement of the

Measuring Instrument is very small, it is impossible to measure the product workpiece. If it is large, then it is too expensive.

2. The accuracy specifications of image measurement instruments must be selected based on the factory's specified measurement product accuracy (each instrument manufacturer's factory specifications and installation specifications, and even the accuracy of the instrument may vary). If the accuracy of your measurement customer's product is not very high, you can choose a general high-precision instrument. If the accuracy of detecting goods is high, it is necessary to purchase high-precision measuring instruments. At present, image measurement instruments have a measurement accuracy of up to 1.5 micrometers.

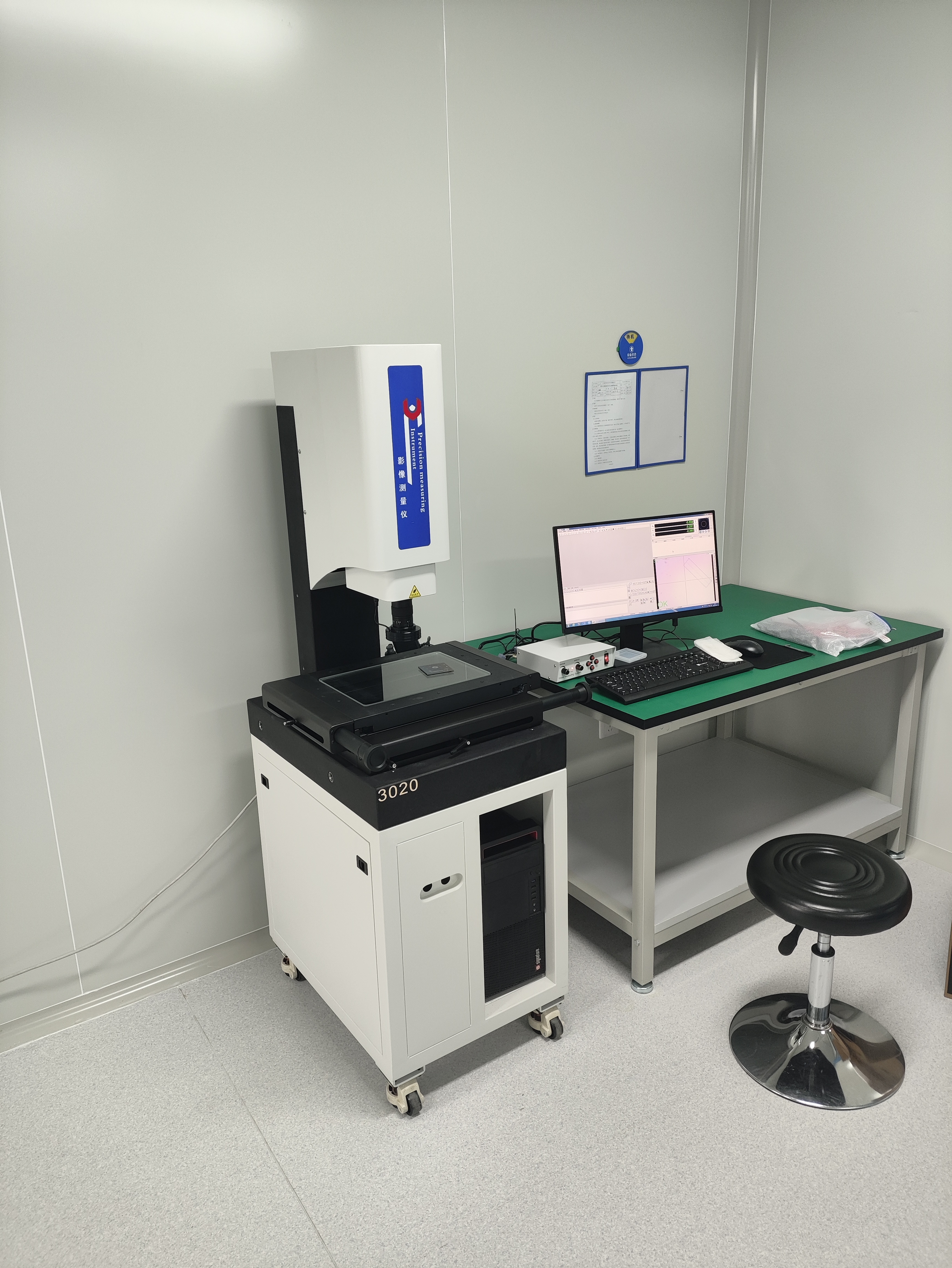

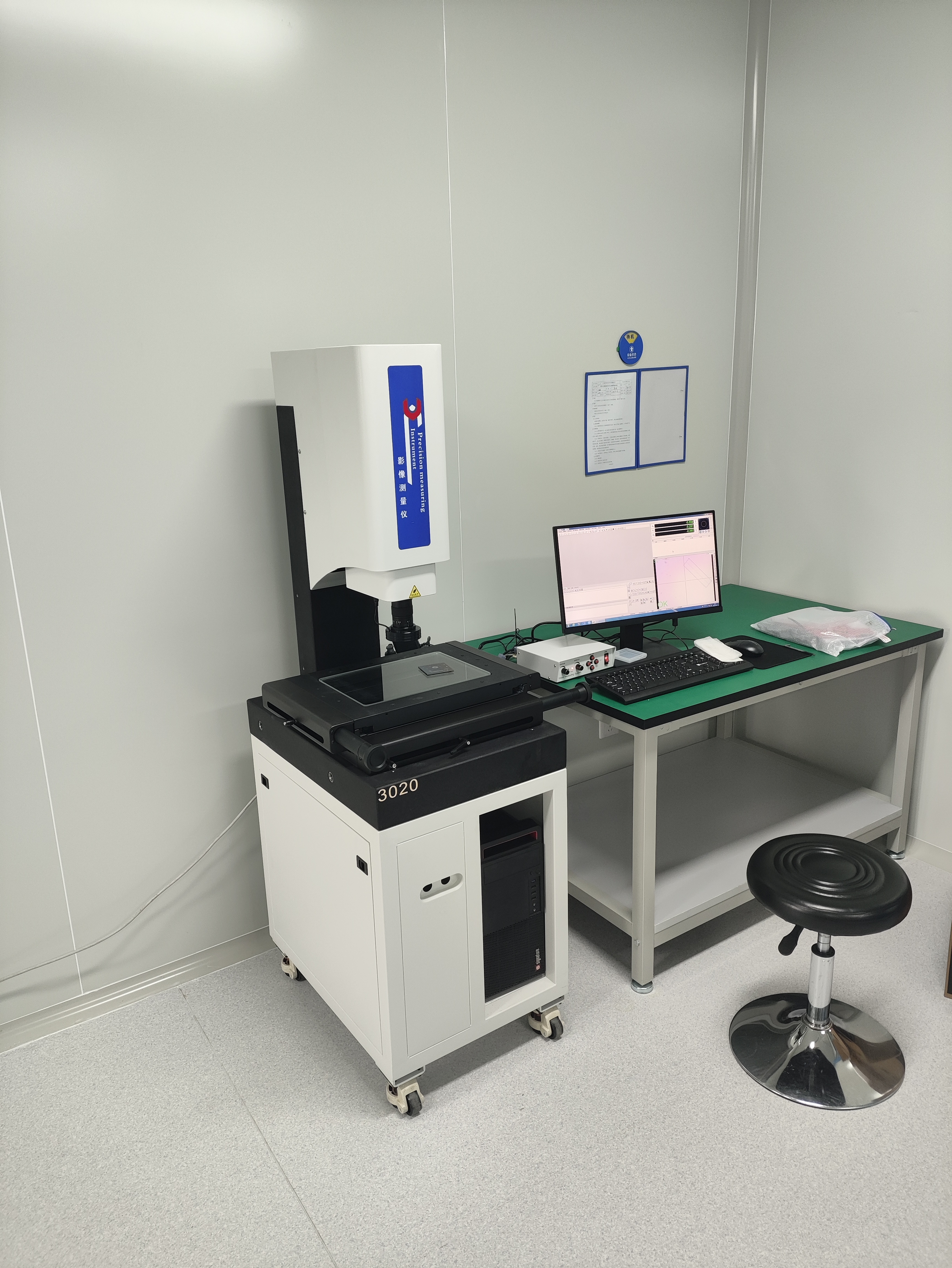

3. In addition to manual control systems, there are also fully automatic image measurement instruments with motor control systems available in the sales market. The price difference between each other is very significant. If customers measure many products, it is best to choose automatic image measurement instruments to ensure high measurement efficiency, and choose self-developed mobile software to obtain stronger compatibility mode and upgrade speed.

4. The general camera lens for manual equipment and automatic machines looking at the instrument camera lens is a continuous ultra wide angle lens and a fixed fixed fixed specification camera lens. In addition to the two types of camera lenses mentioned above, the fully automatic measuring instrument also adopts an automatic ultra wide angle lens, which has a significant price difference between imported and domestic products.

5. The high cost-effectiveness of image measurement instruments during the warranty period must take into account after-sales maintenance services. Low cost, poor instrument accuracy, poor reliability, ensuring after-sales service, and short application cycle; Imported measuring instruments have stable characteristics and a long service life, but they are inconvenient to upgrade and increase maintenance costs.