Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

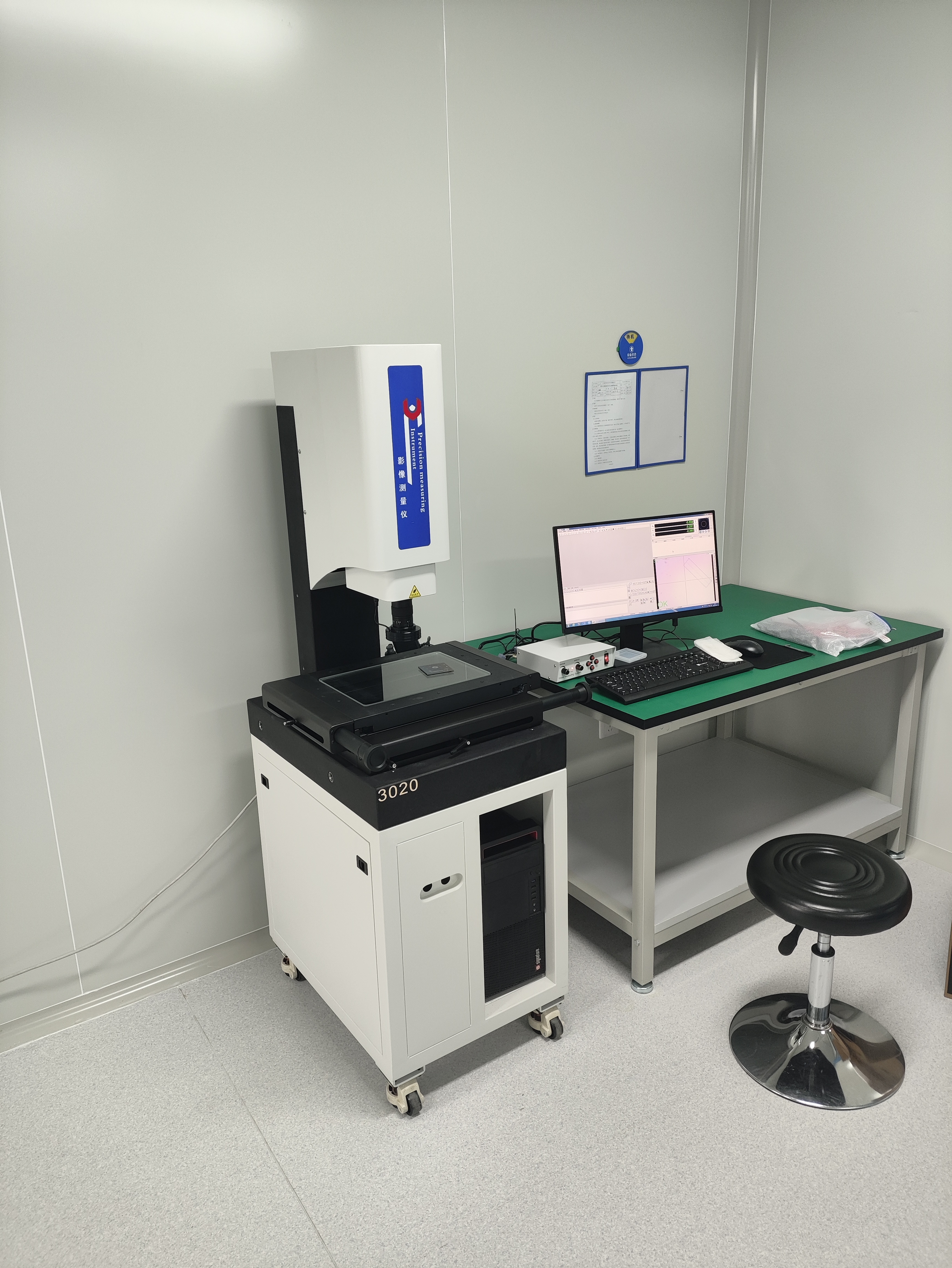

The key development trends of image measurement instrument technology in the small parts industry of the three eye upright analysis microscope are as follows:

1. Further improving measurement accuracy. With the continuous improvement of industrial production standards, the precision requirements for fine parts will be further improved, thereby improving the accuracy of image measurement instrument technology in measuring precision. In addition, with the rapid development trend of image sensor devices, high pixel devices have also set standards for improving the precision of system software. In addition, further scientific research on sub definition and super-resolution technologies will also provide technical guarantees for improving the precision of system software.

2. Improve measurement efficiency. The application of small and medium-sized parts in the field has been improved at the geometric level, and the daily tasks of 100% online measurement and production manufacturing solid models must be efficiently measured. With the improvement of hardware configuration capabilities such as electronic computers and the continuous improvement of image solution optimization algorithms, the efficiency of image measurement instrument system software will be improved. 3. Complete the transformation of micro components from point measurement to overall measurement. The current image measurement instrument technology is limited by measurement precision, and most of the important characteristic areas in small components are imaged to complete the measurement of important characteristic points, which cannot measure all contours or all characteristic points. With the improvement of measurement precision, obtaining detailed images of parts and completing high-precision measurements of overall appearance deviation will be used in more and more industries. In summary, in the field of micro element device measurement, the high efficiency of high-precision image measurement instrument technology is bound to become a key development prospect for high-precision measurement technology. Therefore, the hardware configuration system software for image collection has achieved higher standards for image quality, precise positioning of image edges, and software correction, which have broad application prospects and key research significance. Therefore, this technology has become a network hotspot for scientific research in various countries around the world, and has become one of the most important applications in visual detection technology.

From the moment when the second-dimensional image measuring instrument appeared, the precision measuring instrument really entered the development era of high-precision measuring instrument. It was...

Can a fully automatic 3D image measuring instrument measure height? How much can a typical accuracy cost? Two dimensional measuring instrument, also known as image measuring instrument, is a...

Email to this supplier

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Fill in more information so that we can get in touch with you faster

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.