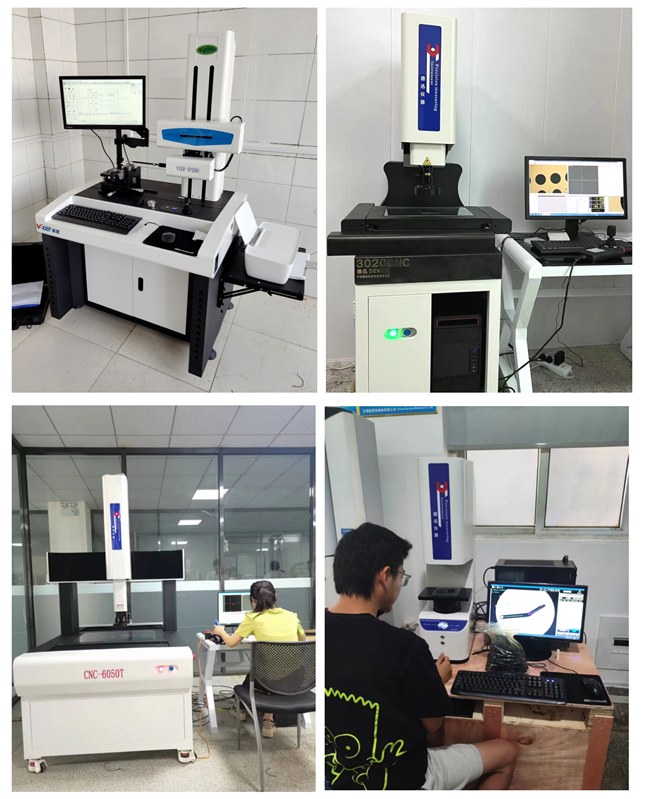

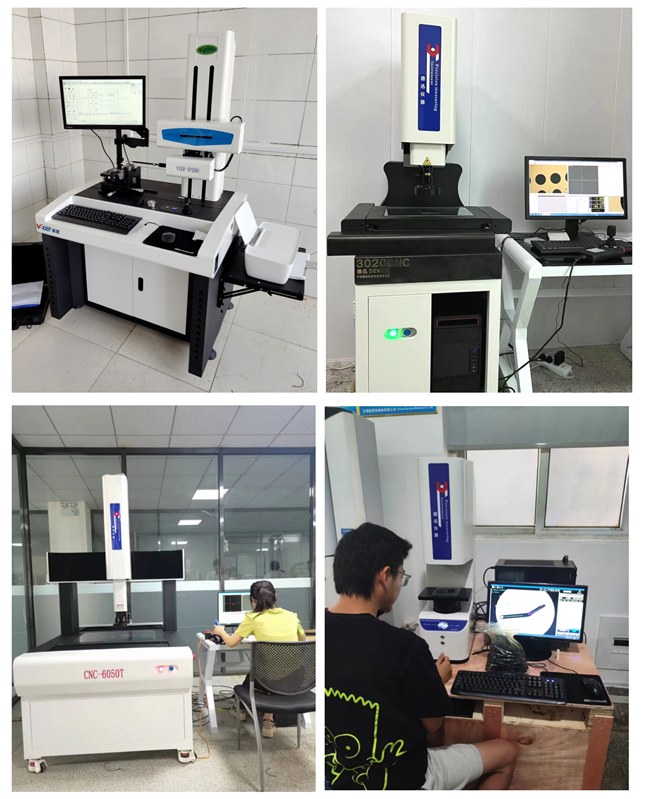

Video measuring instruments are also known as imaging instruments, imaging precision detectors, and electronic optical detectors. In terms of measuring projectors, it has maintained a qualitative leap, from traditional light projection to precise measurement on computer screens based on color images, improving the level of industrial production precision measurement.

The video

Measuring Instrument is a precision testing instrument that integrates light, electricity, and machinery. It must be well maintained to ensure the excellent application of the instrument equipment. In order to maintain the initial precision of the instruments and equipment and increase their lifespan.

Therefore, the routine maintenance of video measuring equipment is crucial, but when the equipment is not working, it is very demanding on the surrounding environment. This natural environment will have a slow shadow box, and if I don't pay attention to the durability of the equipment, it will decrease. The following section provides a detailed explanation of the requirements of imaging for the system's office environment.

Regulations on office environment for digital cameras:

1. Clean natural environment

The video measuring instrument is a highly accurate instrument and equipment, which can use dust staining agents. Once the instrument and equipment slides, wide-angle lenses, etc. are contaminated by smoke and dust environment, it will cause serious harm to precision and imaging. Therefore, it is essential to clean the instruments and equipment on time to maintain a clean natural environment.

2. Reduce environmental pollution from crude oil

The image measuring instrument is very precise, so its directionality, lenses, grating ruler, and plan laminated glass are not prone to environmental pollution of crude oil, otherwise it will endanger all normal applications of the instrument and equipment. Be careful not to touch the equipment with clean hands, preferably with cotton gloves.

3. Photoeffect

Testing instruments should not be directly exposed to the sun, otherwise it will endanger the precision of the instruments and equipment, and long-term high temperatures will damage the instruments and equipment.

4. Temperature control

The working temperature of the testing instrument placement is 18c-24c, and the fully automatic three coordinate system cannot exceed this range, otherwise the precision will be compromised.

5. Environmental humidity

Excessive environmental humidity can also harm the precision of instruments and equipment, and excessive environmental humidity in natural environments can cause rusting. Therefore, the relative humidity of the general air should be controlled between 45% and 75%.

6. Vibration

If the instrument and equipment are exposed to vibration in a natural environment for a long time, its components will be damaged and its precision will be reduced. Preventing earthquake disasters is necessary. When the frequency is below 10Hz, the amplitude of the gantry image measuring instrument is less than 2 μ M. The instantaneous speed is less than 0.4 gal. 10Hz-50Hz. When you cannot manipulate this vibration natural environment, install vibration hydraulic dampers to reduce vibration.

The above content is the regulations for the office environment of video measuring equipment.