In the field of instrument equipment, precision measuring instruments are a very new type of equipment, and they are also widely used in the processing and manufacturing industry, providing quality gantry image measuring instruments with safety assurance for the testing of workpiece products. In precision measurement instruments, the high-precision measurement instruments commonly known include 2.5-dimensional image measuring instruments and 3-coordinate measuring machines, which are also the two most critical categories of measurement instruments in precision measurement instruments.

Among them, the 2.5-dimensional image

Measuring Instrument is mainly used for precise two-dimensional measurement of workpiece products, while the three-dimensional measuring instrument is mainly used for three-dimensional detection of key workpiece products. Compared with the 3-coordinate measuring instrument, what is the key influence of the anime imager in the development trend of high-precision measuring instruments, and what is the role of the manual imager in the development trend of the entire enterprise of high-precision measuring instruments? Compared with the three-dimensional measuring instrument, we can see from the basic function of accurate measurement of the anime imager that the basic function of accurate measurement of the imager is slightly simpler than the three-dimensional measuring instrument, because it can only easily test the two-dimensional information of the workpiece product. However, in the development trend of high-precision measuring instruments, the influence and role of the anime imager is not as simple as that of the CMM.

At the beginning of the development trend of precision measurement instruments, people could only rely on a simple and rough projector to achieve many simple and accurate measurements. This greatly limits the quality assurance of the company's products for both the market and users. So, on this basis, the 2.5-dimensional measuring instrument was developed by technical personnel and production and processing manufacturers, suddenly becoming a fashionable darling among high-precision measuring instruments. At present, 2.5-dimensional measurement instruments still belong to simple measurement instruments, but in the current situation, it has made a significant breakthrough on the basis of the original projector. It has greatly improved the accuracy and complexity of precise measurement results, and it is from this time that precision measurement instruments have truly entered the era of high-precision measurement instruments.

From here, we can see that the anime imager has an irreplaceable influence in the development trend of high-precision measuring instruments. At the same time, it is precisely due to the emergence of 2.5-dimensional measuring instruments that people have developed, produced, and processed more high-end high-precision measuring instruments such as CNC 2.5-dimensional, manual three-dimensional, and CNC three-dimensional. From this, we can draw a conclusion that the anime imager not only has a high influence in the development trend of high-precision measuring instruments, but also plays an active role in promoting the development trend of high-precision measuring instruments, making the development trend of high-precision measuring instruments continuously obtain one step after another.

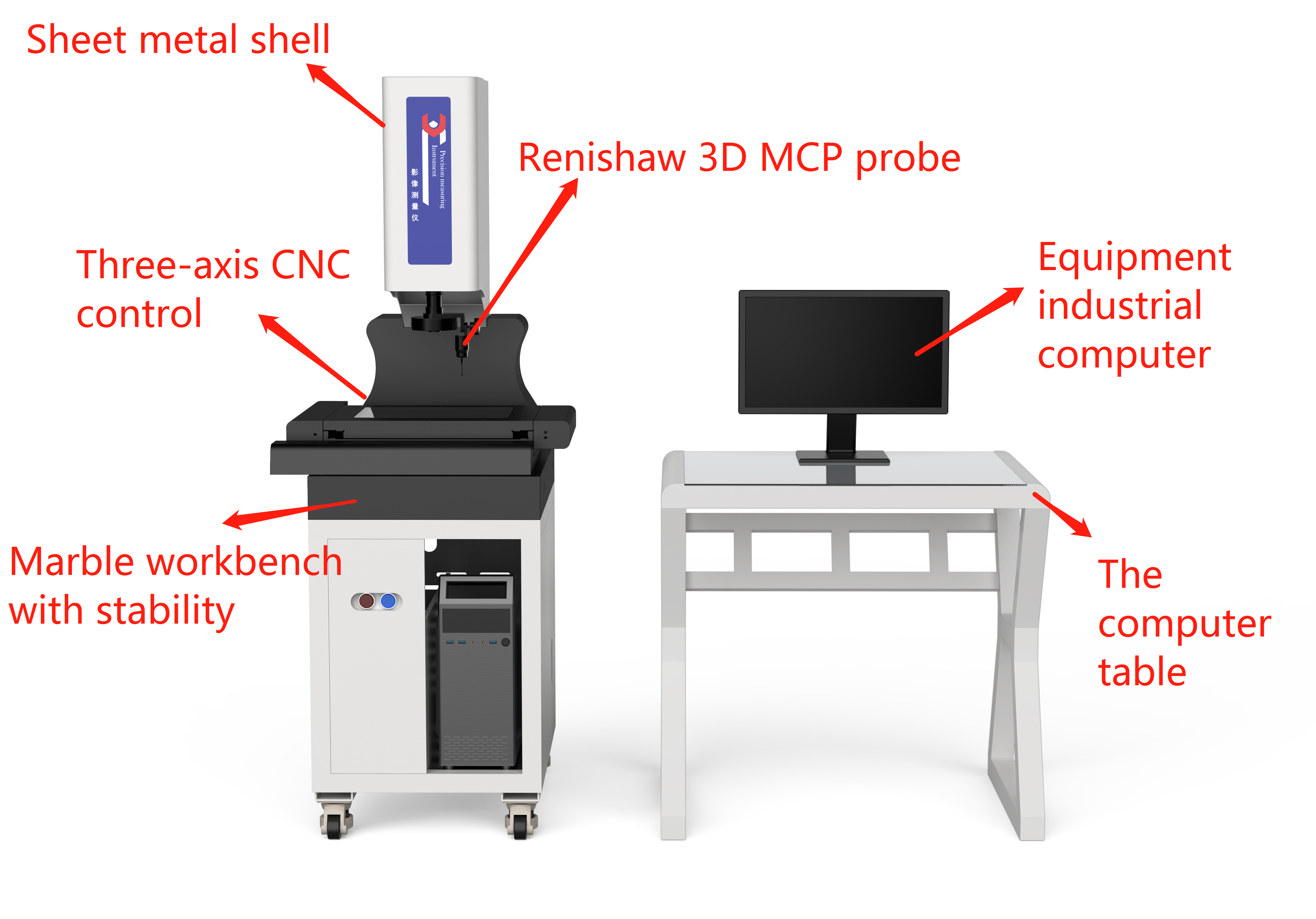

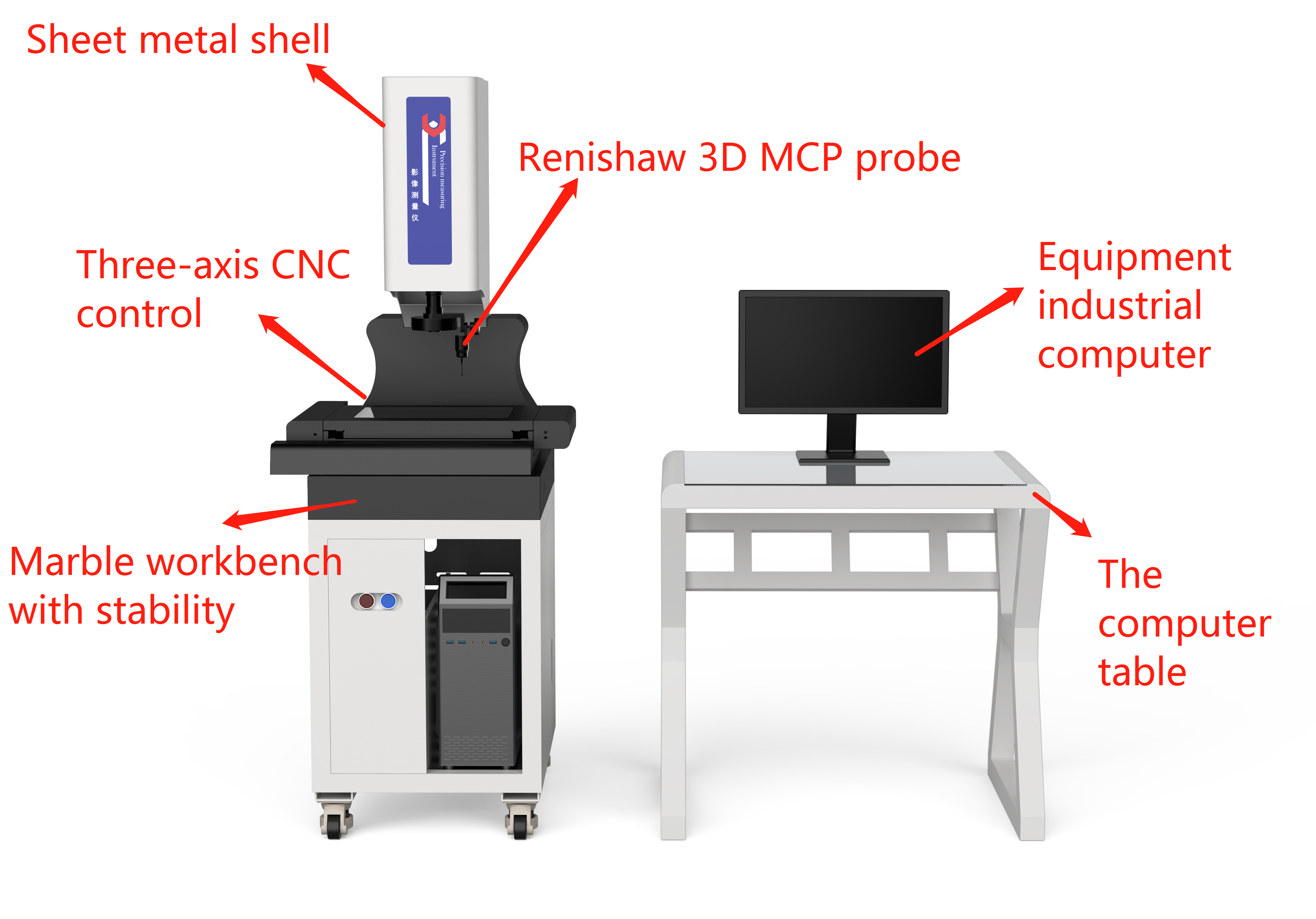

The main purpose of coordinate measuring machines is to be widely used in enterprises such as sedans, electronics, hardware tools, plastics, injection molds, etc. It can accurately test the dimensions, appearance, and positional accuracy of workpiece products, thereby achieving tasks such as component testing, accurate measurement of appearance, and process control.

Accurately measure high-precision geometric parts and surfaces; Mechanical molds that accurately measure complex appearances; Testing free form surfaces; You can select touch or non touch probes for multiple scans.